Rupice Maiden Resource

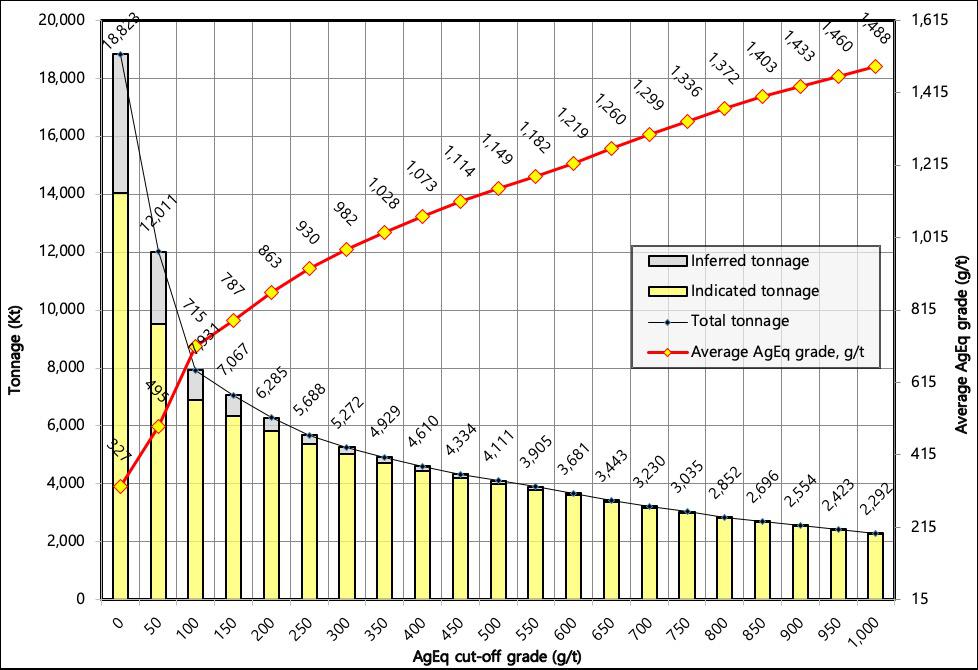

The updated Indicated and Inferred Mineral Resource estimate was prepared by CSA Global in Perth and comprises 12.0 Mt at 149 g/t Ag, 1.4g/t Au, 4.1% Zn and 2.6% Pb, as set out in Table 1.

Table 1 - Rupice updated MRE by Classification

Notes:

- Mineral Resources are based on JORC Code definitions.

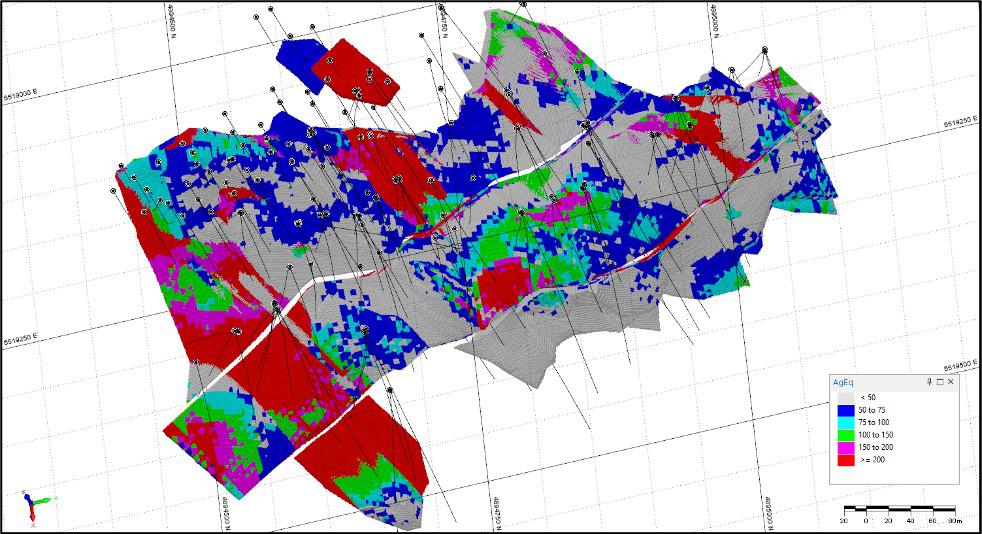

- A cut-off grade of 50g/t silver equivalent has been applied.

- AgEq – Silver equivalent was calculated using conversion factors of 31.1 for Zn, 24.88 for Pb, 80.0 for Au, 1.87 for BaSO4, 80.87 for Cu and 80.87 for Sb, and recoveries of 90% for all elements. Metal prices used were US$2,500/t for Zn, US$2,000/t for Pb, $150/t for BaSO4, $2,000/oz for Au, $25/oz for Ag, $6500/t for Sb and $6,500 for Cu.

- The applied formula was: AgEq = Ag(g/t) * 90% + 31.1 * Zn(%) * 90% + 24.88 * Pb(%) * 90% + 1.87 * BaSO4% * 90% + 80 * Au(g/t) * 90% + 80.87 * Sb(%) * 90% + 80.87 * Cu(%)* 90%

- It is the opinion of Adriatic Metals and the Competent Persons that all elements and products included in the metal equivalent formula have a reasonable potential to be recovered and sold.

- Metallurgical recoveries of 90% have been applied in the metal equivalent formula based on recent and ongoing test work results.

- A bulk density was calculated for each model cell using regression formula BD = 2.745 + BaSO4 * 0.01793 + Pb * 0.06728 - Zn * 0.01317 + Cu * 0.1105 for the halo domain, BD = 2.7341 + BaSO4 * 0.01823 + Pb * 0.04801 + Zn * 0.03941 - Cu * 0.01051 for the fault zones and BD = 2.7949 + BaSO4 * 0.01599 + Pb * 0.05419 + Zn * 0.01169 + Cu * 0.06303 for the low grade domain. Bulk density values were interpolated to the combined high-grade domain from 631 BD measurements.

- Rows and columns may not add up exactly due to rounding.

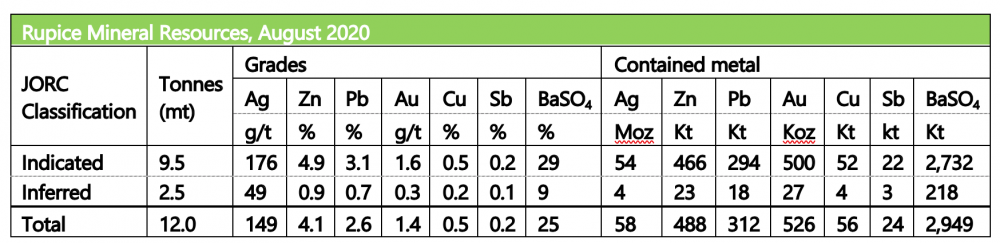

Figure 1 – Plan View of the New Ore Block Model Outline of Rupice vs 2019 Ore Block Model

RUPICE DRILLING AND SAMPLING

For the Mineral Resource estimate, a total of 167 diamond drill holes (46 historical drill holes and 121 drill holes from the Company’s drilling programmes in 2017 (8 holes), 2018 (39 holes), 2019 (52 holes) and 2020 (22 holes)) for 38,135m define the current limits of the known mineralisation. The deposit was drilled and sampled using diamond drill holes at a nominal 20m by 20m spacing.

Drill holes drilled by the Company were generally angled –50° to –80° mostly towards the southwest with dip angles set to optimally intersect the mineralised bodies. Additional drill holes were drilled from the opposite direction, and perpendicular to the mineralised trend. All the historical holes were vertical and focussed on the up-dip portion of the Rupice mineralisation.

The drill core was sampled for assay; whole core for the historical drilling and half core (HQ and PQ) for the recent drilling. Recent assays were sent to ALS in Bor, Serbia for multi-element analyses.

RUPICE GEOLOGY AND MINERALISATION

The host rocks at Rupice comprises Middle Triassic limestone, dolostone, calcareous and dolomitic marl, and a range of mostly fine-grained siliciclastic rocks including cherty mudstone, mudstone, siltstone and fine-grained sandstone. The main mineralised horizon is a brecciated dolomitic unit that dips at around 50o to the northeast and has been preferentially mineralised with base, precious and transitional metals. The Triassic sequence has been intensely deformed both by early stage ductile shearing and late stage brittle faulting.

The Rupice polymetallic mineralisation consists of sphalerite, galena, barite and chalcopyrite with silver, gold, tetrahedrite, boulangerite and bournonite, with pyrite. The majority of the high-grade mineralisation is hosted within the brecciated dolomitic unit, which is offset and cut by northwest striking, westerly dipping syn-post mineral faulting. This faulting displaces the mineralised body up to 20 metres in places. Thickening of the central portion of the orebody occurs where these faults flexure and deform. Mineralised widths up to 65 metres true thickness are seen in the central portion of the orebody.

To date, the massive sulphide mineralisation at Rupice has a defined strike length of 650 metres, with an average true-width thickness of around 20 metres. However, mineralisation at Rupice still remains open towards the north and down-dip to the south.

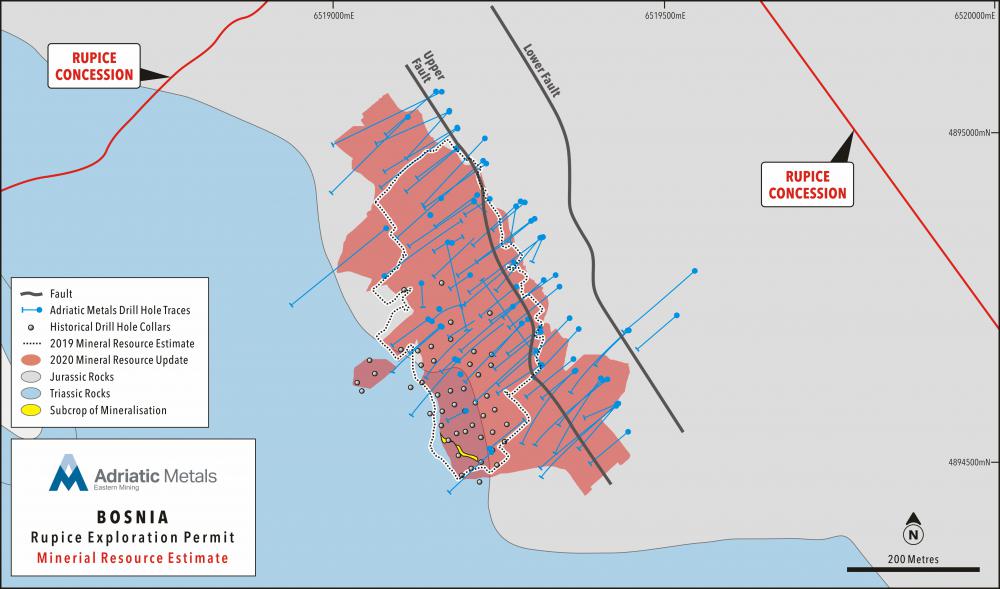

Figure 2 - Rupice Ore Block Model by AgEq Grade Ranges

RUPICE MODELLING AND GRADE INTERPOLATION

The main geological features that control the polymetallic mineralisation at Rupice were interpreted using geological and structural data collected. Three main domains were interpreted and wireframed individually; the main mineralised brecciated dolomitic units, that hosts the high-grade mineralisation; the fault zones that off-set and displace these main mineralised bodies; and a lower-grade halos peripheral and in the footwall of the main mineralised bodies.

Statistical analysis of modelled domains showed that the main mineralised brecciated dolomite has a bimodal population for the majority of the elements being modelled. The higher-grade populations clustered spatially and were subsequently individually interpreted and wireframed.

Ten elements were modelled; Ag, Zn, Pb, BaSO4, Cu, Au, Sb, Hg, As and S, and the higher-grade populations were interpreted and wireframed for all elements except Hg, As and Sb.

All the domains were interpreted on a section by section basis and were used to generate 3D ‘solid’ wireframes. The same methodology was applied for the individual high-grade populations.

Once mineralisation for each element was interpreted and wireframed, classical statistical analysis was repeated for the samples within the interpreted domains. Drill data was composited to 2m down hole intervals. Boundary statistical analyses and top cuts were determined and applied.

The geostatistical analysis generated a series of semi-variograms that were used during grade estimation using Ordinary Kriging (“OK”). The semi-variogram ranges determined from the analysis contribute heavily to the determination of the search neighbourhood dimensions. All variograms were calculated and modelled for the composited sample file, constrained by the corresponding mineralised envelopes for each element. Where low-grade and high-grade domains were modelled, samples were combined for both domains to make sure that the number of samples was sufficient for robust geostatistical analysis. It was found that absolute semi-variograms were difficult to model for most of elements, and therefore, relative semi-variograms were modelled for Pb, BaSO4, Ag, Au, Sb, Hg, As and Cu. Absolute variograms were modelled for Zn and S.

The density values were calculated for each model cell using a regression formula for all the domains except the combined high-grade domain. The formula was calculated using scattergrams for density versus BaSO4, Pb, Cu and Zn grades. Density values were interpolated within the limits of the combined high-grade domain.

A block model was constructed, constrained by the interpreted mineralised envelopes. A parent cell size of 5 m(E) x 5 m(N) x 5 m(RL) was adopted with standard sub-celling to 1 m(E) x 1 m(N) x 1 m(RL) to maintain the volumetric resolution of the mineralised lenses.

Grades for all ten elements were interpolated into the empty block model using the Ordinary Kriging method and a “parent block estimation” technique, i.e. all sub-cells within a parent cell were populated with the same grade. The OK process was performed at different search radii until all cells were interpolated. The search radii were determined by means of the evaluation of the semi-variogram parameters, which determined the kriging weights to be applied to samples at specified distances.

Block grades were validated both visually and statistically and all modelling was completed using Micromine software.

RUPICE CLASSIFICATION AND REPORTING

Clause 20 of the JORC (2012) Code requires that all reports of Mineral Resources must have reasonable prospects for eventual economic extraction, regardless of the classification of the resource. The Rupice deposit has reasonable prospects for eventual economic extraction on the following basis:

Metallurgical test work by WAI has confirmed that the Rupice mineralisation is amenable to flotation processes;

Preliminary metallurgical test work has confirmed that a barite concentrate should meet API specifications;

A marketing study by a leading consultant in the field of barite confirmed that there is an opportunity to enter the market as a niche player levering any logistical advantages for a supplier in Bosnia & Herzegovina;

The cut-off grade adopted for reporting (50g/t Ag equivalent) is considered reasonable given the Mineral Resource will most likely be exploited by underground mining methods and processed using flotation techniques.

The Scoping Study demonstrated that the deposit potentially has a positive net present value (NPV), and that the mineralised zone is potentially mineable using underground methods under the given economic scenario and parameters. CSA Global did not estimate Ore Reserves for the deposit. The deposit appears to have reasonable prospects of eventual economic extraction under a realistic set of criteria.

The Rupice Mineral Resource has been classified based on the guidelines specified in the JORC Code. The classification level is based upon an assessment of geological understanding of the deposit, geological and mineralisation continuity, drill hole spacing, QC results, search and interpolation parameters and an analysis of available density information. The MRE is reported by classification in Table 1, above a cut-off grade of 50g/t silver equivalent.

Figure 3 – Grade Tonnage Curve with AgEq Grades