DFS - Infrastructure and Logistics

Bosnian Definitive Feasibility Study

9 September 2021

Rupice Surface Infrastructure and Vares Processing Plant sites are located approximately 8.7 km west-north-west and 3.5 km east of the town of Vares, respectively, which is 35 km north-north-west of the capital city Sarajevo.

The Vares Processing Plant site is accessed from the main sealed road (R444) connecting the town of Vares to the capital city of Sarajevo. From the R444, a secondary sealed road runs east, past Tisovci village, and to the site.

The Vares Processing Plant’s dedicated access road from the public road has recently been upgraded by the Company.

Rupice Surface Infrastructure site is largely a greenfield site, located 1.5 km from the nearest small village of Borovica Gornja. No infrastructure currently exists at Rupice. It is currently accessed from the main sealed road, travelling north from Sarajevo on the R444 and then turning west onto the R444a, north of Vares. From the R444a, a secondary sealed road accesses the village of Borovica Gornja.

There are no waterways or channels within close proximity to the project area and all construction material, equipment and consumables will be transported via rail or heavy truck and trailer from point of supply in Europe or Ploce port located on the coast of Croatia.

Power Supply

Power for the Rupice Surface Infrastructure will be provided from a new, buried 35 kV powerline which will run from Vares Majdan regional sub-station, follow the route of the new haul-road between Rupice Mine and Vares Processing Plant and be terminated at a new Rupice sub-station. The cost of this new power supply from the Vares Majdan sub-station will be for the Project. Modifications at the Vares Majdan sub-station will be covered by the power supply company, JP Elektroprivreda BiH d.d, who completed a study for the work which was subsequently fully costed by the local contractor.

From the new sub-station at Rupice, power is reticulated at 10 kV on overhead powerlines to the Rupice Surface Infrastructure, Underground Mine, backfill plant and crushing plant. The electricity supply underground is at 1,000 V.

At the Vares Processing Plant, the existing 35 kV overhead powerline supplying the historic site will be upgraded, new incoming transformers will be installed and feeders to the main processing plant sub-station and other ancillary supplies will be provided at 10 kV.

In addition to the supply of equipment, a connection fee is payable at both locations at a rate of BAM 140 per kW.

Water Supply

Water supply for Rupice Surface Infrastructure will come from the Studenac stream near Pogar. The site was previously a source of water for the town of Vares. It will be operated by JKP Vares d.o.o., the local municipal contractor and supply water to Rupice Site Infrastructure via a new pump and 5 km long pipeline.

The existing municipal water supply to the Vares Processing Plant site will be utilised for supply of all water for the plant and infrastructure operations.

Both sites can supply sufficient water to meet the needs at the sites.

Fire Water

At Rupice Surface Infrastructure, a fire water ring main with hydrants will be provided around the site with hydrants at 50 m intervals and 50 m firehoses provided. The system will be fed from a fire-pump arrangement with electrical, diesel pumps and a jockey pump located at a dedicated fire water tank. The design of the system has been completed by a design institute in Bosnia & Herzegovina to both local and international standards. Buildings and vehicles will be equipped with fire extinguishers.

At the Vares Processing Plant site, a fire water ring main with hydrants will be provided around the site with hydrants at 50 m intervals and 50 m firehoses provided. The system will be fed from the municipal water supply pipeline which provides sufficient flow and is in turn supplied from a hill-side water tank of sufficient size. The design of the system has been completed by a design institute in Bosnia & Herzegovina to both local and international standards. Buildings and vehicles will be equipped with fire extinguishers.

Sewage

At Rupice Surface Infrastructure, a containerised sewage treatment plant will be provided and an all-new sewerage reticulation system.

At the Vares Processing Plant site, there is an existing sewerage reticulation system with septic tanks and a soak away. It was inspected and cleaned out in 2020. The new facilities will tie-in to this existing system. Staffing numbers are expected to be less than was here for the historic operations.

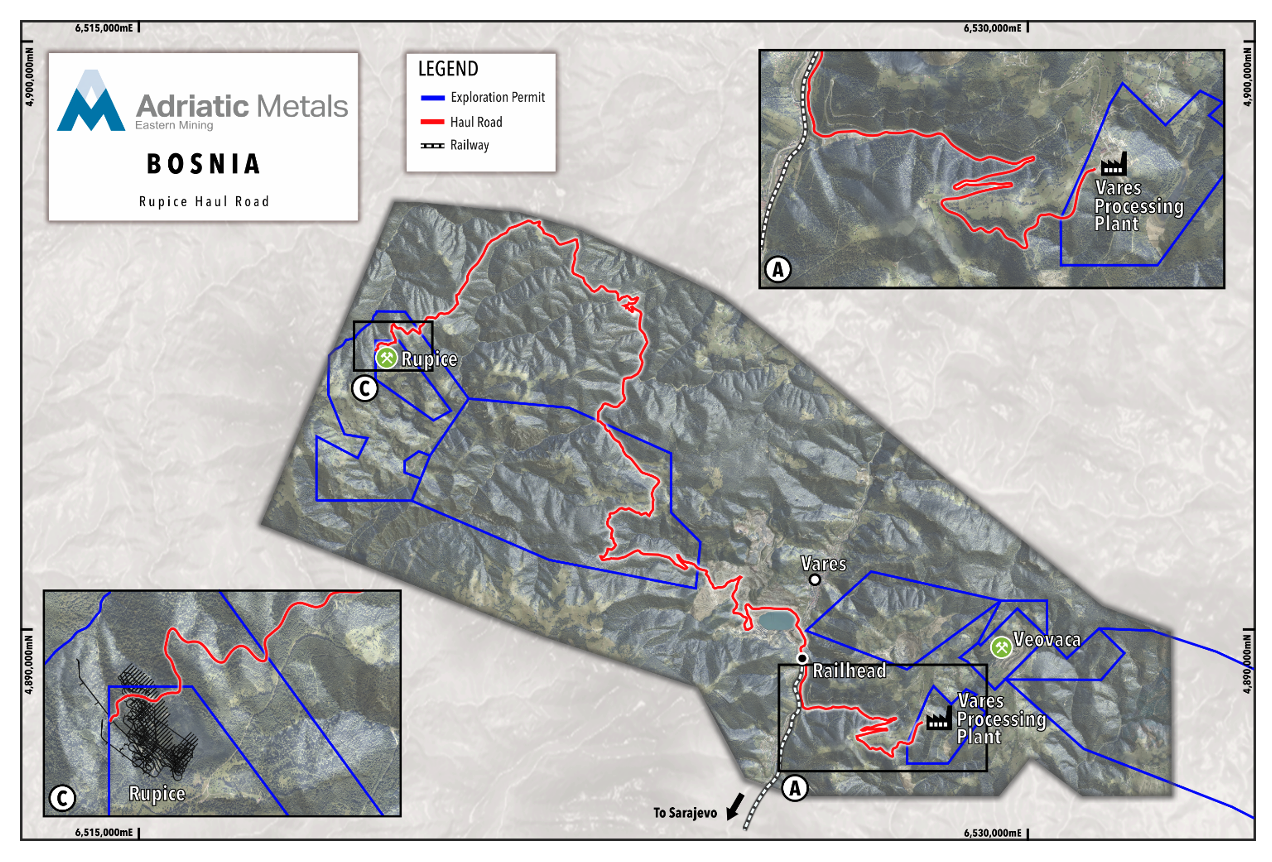

Haul-road

A new haul-road of 24.5 km will be built for transporting crushed ore and dewatered tailings between the Rupice Surface Infrastructure and the Vares Processing Plant, as well as transporting full and empty concentrate containers between the Vares Processing Plant to the Vares Railhead. It is also planned that shipments of reagents, consumables, spare parts etc. will be delivered in containers to the railhead for onward movement to Rupice Mine and Vares Processing Plant using the haul-road.

The haul-road will consist of sealed and unsealed sections, which by-pass villages and dwellings as well as the town of Vares. The 24.5 km of haul-road will be made up of both newly constructed (15.5 km) and upgraded (9 km) sections. It will be permitted, constructed and owned by the Municipality of Vares, and the Company will provide funding and oversight of its construction and ongoing maintenance during life of mine.

The haul-road will be a restricted use road, meaning that whilst open to the public there will be adequate warnings that it is used by mining trucks.

The Rupice Surface Infrastructure site will be accessible all year round, except for occasional days in winter following high snowfall events until all roads can be cleared. JKP Vares will be responsible for snow clearance of the road. Sufficient stockpile capacity exists on each site to ensure continuity of operations.

Figure 12: Topography map showing the haul-road route between Rupice and Vares Processing Plant

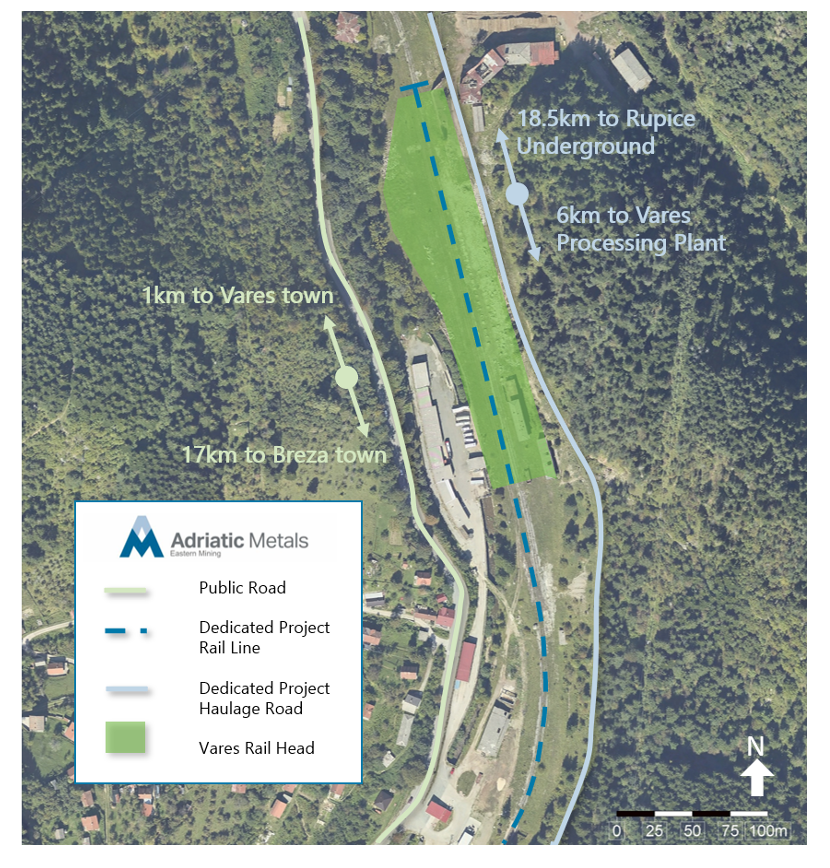

Product Loadout and Vares Railhead

The Vares Railhead is the former site of the Droskovac Railway Station, located between the town of Vares and Vares Majdan. The Railways Federation Bosnia and Herzegovina (“Railways FBiH”) own the railway line and rail infrastructure in Vares. The Company proposes to use the land surrounding the Droskovac Railway Station for temporary storage and loading of containers onto the wagons.

A scoping study for the design of the 4,000 m2 Vares Railhead facility has been completed and detailed engineering is underway for the refurbishment of the sidings, erection of security fences and lighting, concrete pads for container storage and site offices.

The silver-lead and zinc concentrates will each be loaded into lined Twenty-foot Equivalent Unit (“TEU”) containers at the Vares Processing Plant. They will then be transported 6 km downhill along the haul-road to the Vares Railhead, where the containers will be either stored or cross-loaded directly by reach-stackers onto awaiting rail wagons. A one-way traffic circuit will be implemented by linking up with the haul-road that runs above and parallel to the eastern boundary of the Vares Railhead.

A maximum of 900 wet metric tonnes of concentrate, stored in containers (36 containers, each containing 25 t of concentrate), can be transported by rail with each rail movement.

Initial negotiations have been conducted with the Ministry of Finance for the designation of the Vares Railhead as a customs free zone, and an application will be made in due course.

Figure 13: Plan View of the Vares Railhead

Rail

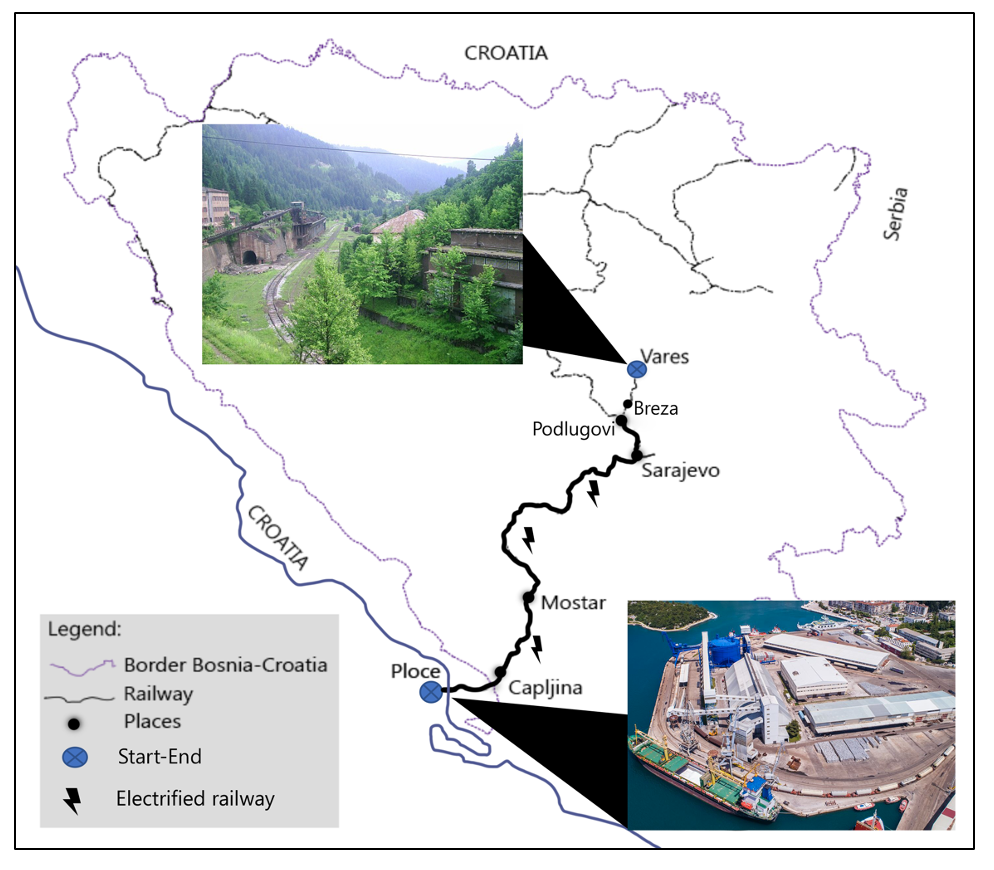

The rail journey from the Vares Railhead to the Ploce Port passes through three locations where locomotives will be changed according to the line requirements.

The first 25 km section of the line from Vares to Podlugovi uses diesel locomotives and was last used in 2012. This section of line requires upgrading in places. Railways FBiH have surveyed the route and consider this to be easily completed within a short timescale. The Company has an agreement with BiH Railways that the Company provides them with three months’ notice prior to use and in-turn Railways FBiH will complete the upgrade work within two months.

The remaining journey to the Ploce Port will be on electrified lines, with regular other freight traffic until final exchange at the Bosnian/Croatian border to the port’s own diesel engines. The complete journey from the Vares Railhead to the Ploce Port will take approximately 10 hours. Commercial terms have been agreed with Railways FBiH, including the design and consequent refurbishment of the Vares Railhead.

Figure 14: Map of the rail route from Vares to Ploce

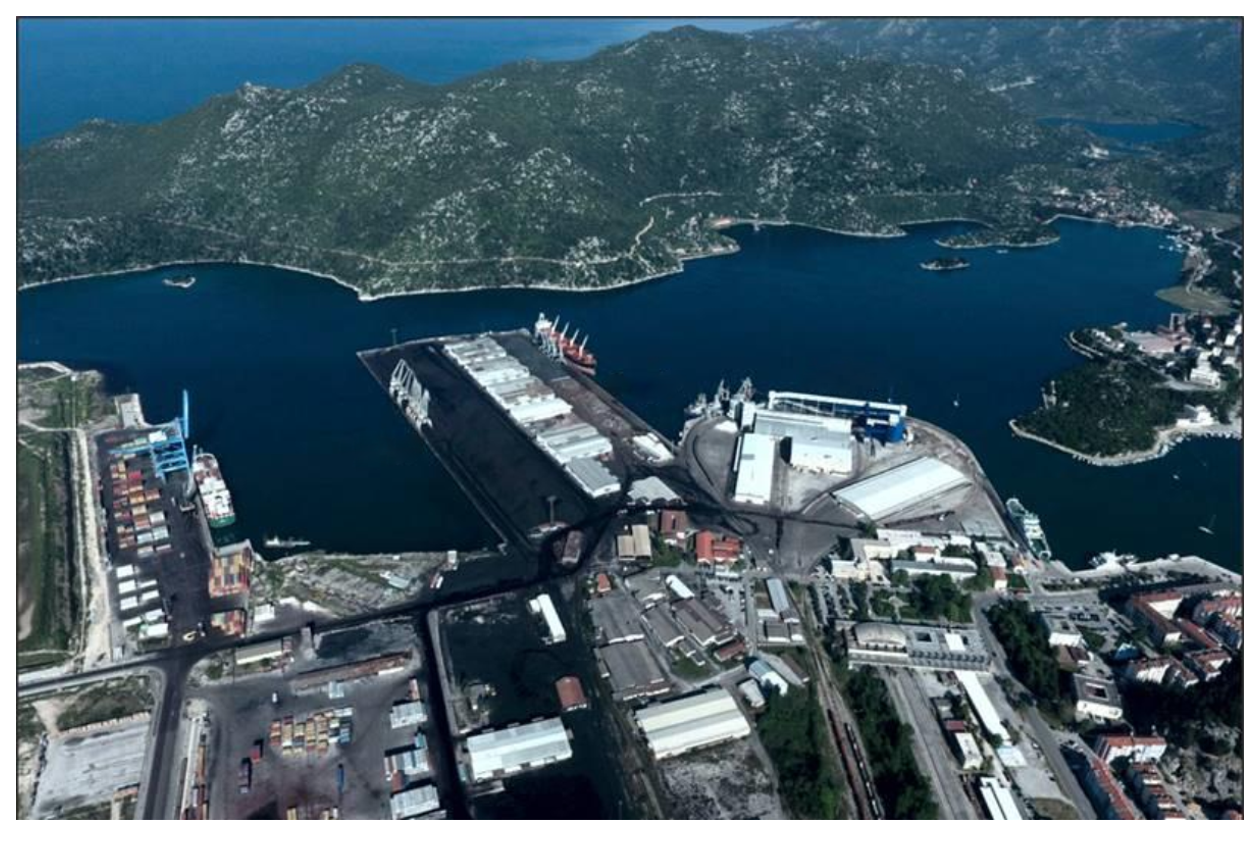

Port

Ploce Port is located on the Croatian Adriatic coast, located near the mouth of the Neretva River. It has extensive railway sidings, dedicated road and rail access, modern security measures and provides full stevedoring services. It is a sheltered deep-water port, with depth of up to 17.8 m, allowing vessels as large as Capesize (100,000 dwt) to berth. The container terminal has a length of 280 m and depth of 14 m. The port operates 24/7 362 days a year. All the main thoroughfares and terminals are floodlit. The port benefits from a large, well equipped, dedicated fire service.

Figure 15: Aerial view of the Ploce Port. The container terminal is on the left-hand side. The other 4 quays are bulk terminals. (Photo: Wilhelmsen Ship Service 2021)

Ploce Port has been the recipient of recent funding from both EBRD and IFC. The funding provided an infrastructure upgrade, which included increasing the container terminal annual capacity to 60,000 TEU, with a new TEREX crane (as shown in Figure 16), Hyster reach stackers as well as other new plant and vehicles. On average the container port is serviced by 1.5 Adriatic Feeders ships per week at a loading rate of 20 TEUs per hour.

The port’s container terminal is operating at just under 50% of capacity. In 2020, port container traffic was approximately 28,000 TEU. In recent years the peak traffic was 35,124 TEU in 2008. There is more than adequate capacity for the concentrates produced by the Vares Processing Plant. During the peak year, the Vares Silver Project will require 7,520 TEU of capacity.

The Company have finalised commercial negotiations with the port operator for the costs associated with the loading and discharging of containers and bulk shipments. Containers will be unloaded from the train to a secured container storage facility and placed into stacks in preparation for onward shipping to their final destination. The railway siding for loading/unloading containers is easily accessible, well maintained and located 150 metres from the container storage facility.

The bulk terminal is similarly under-utilised, currently only supporting coal cross-decking and scrap steel exports. Historically, bulk cargoes shipped through the Ploce Port have included bauxite, iron ore, lead and zinc concentrates. Therefore, the option exists to ship the concentrates though the bulk terminal.

Figure 16: Loading of an Adriatic Feeder at the Ploce Port. Source: Adriatic Metals

Sea Freight

The Company contracted an independent shipping consultant to provide analysis of the shipping markets, targeting a list of ports derived from the negotiations with the potential off-takers. A ship broker also provided contemporary shipping rates. Broadly the independent analysis ascertained high intra-Europe container rates, but economic Main Port China ones and economic intra-Europe bulk rates. The broker, however, provided far more competitive European rates. It is highly likely that improvements can be made if shipments are made to one port, allowing the negotiation of a Contract of Affreightment (discount for volume).

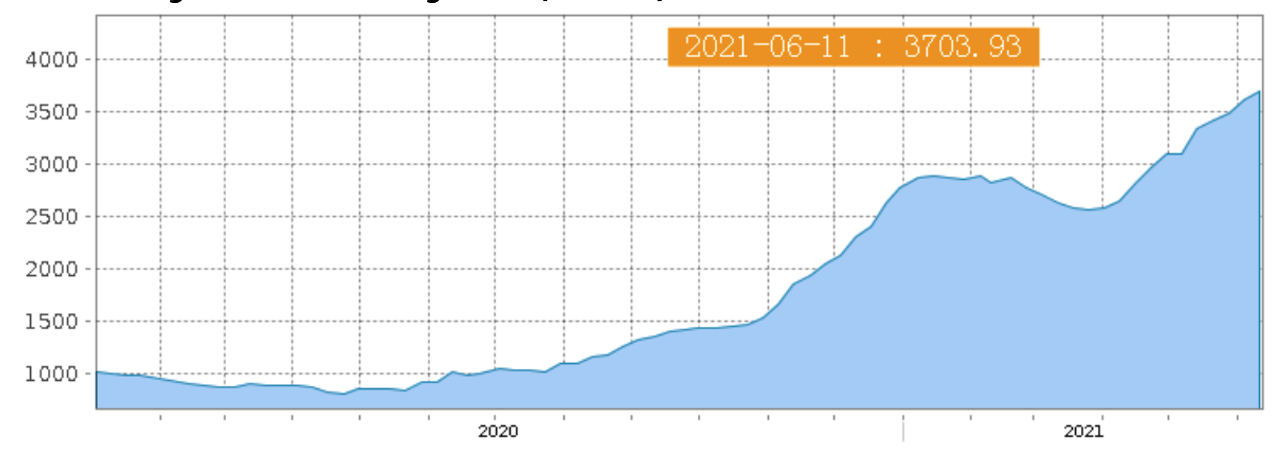

Chart 8: Shanghai Containerized Freight Index (June 2021)

Average containerised freight costs have increased by circa 350% since 1 January 2020. The main drivers of containerised freight cost increases can be summarised as follows:

- The upward super-cycle is being driven by a switch in consumer spending away from tourism, hospitality and travel, towards consumer durables, increasing trade demand significantly during the COVID-19 pandemic.

- Logistics and port bottlenecks and supply chain delays caused by reduced productivity at ports and terminals, warehousing and distribution networks associated with staff shortages resulting from the COVID-19 pandemic.

- Following from above, container movements are taking longer and access to empty equipment (containers) has become increasingly difficult.

- The surge in demand to secure empty equipment for export bookings has resulted in higher prices and further impacted supply chain delays.

- Port disruption in Southern China, mainly Shenzhen and Guangdong manufacturing hubs, with port productivity in the region being significantly impacted (negatively) by transmission of COVID-19 pandemic, with some ports being forced to close for periods of time.

- The Suez Canal blockage earlier this year disrupted supply of equipment and vessel space.

The independent consultant expects shipping lines to maintain a portion of the recent gains in the longer term. Liner shipping companies may be reluctant to see the current strong earnings erode quickly and it is expected that freight costs will remain relatively high in the medium term as liner companies marginally reduce freight rates when the COVID-19 pandemic situation eases. When supply chain disruptions ease circa 2022 and post-pandemic consumer spending begins to normalise, the consultant expects container freight costs to fall by ~10-20%, and from 2023 onwards, container freight levels to increase in line with average inflation levels.