2023 Rupice Mineral Resource Estimate (‘MRE’) Update

Bosnian Maiden Resource Estimates

27 July 2023

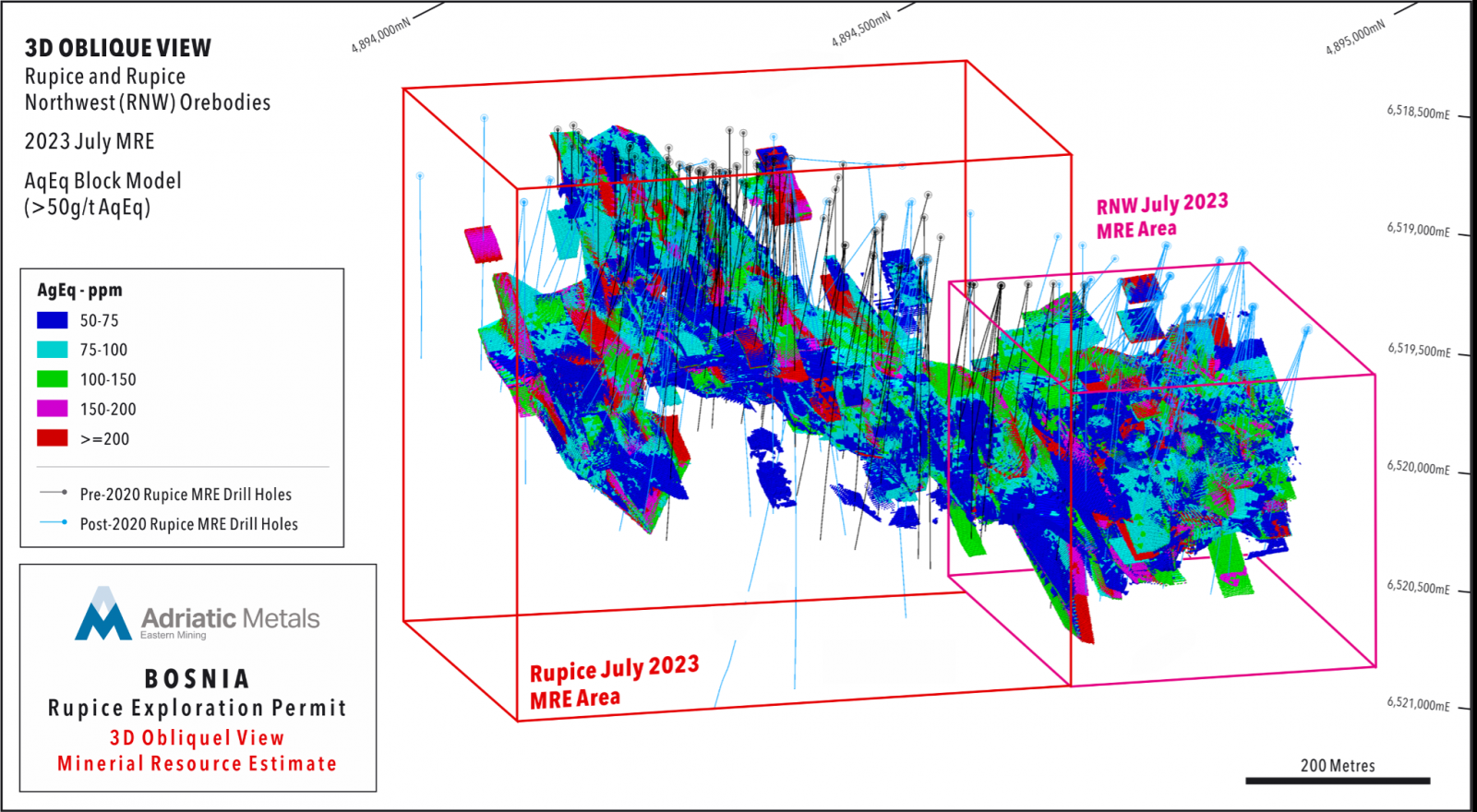

The Indicated and Inferred Mineral Resource estimate (“MRE”) for Adriatic Metals’ 100%-owned Rupice silver-zinc-lead-gold deposit in Bosnia and Herzegovina now stands at: 21.1 Mt at 156 g/t Ag, 1.2 g/t Au, 4.3% Zn, 2.8% Pb, 0.4% Cu, 27% BaSO4 (reported above a cut-off grade of 50 g/t AgEq) containing 105 Moz Ag, 789koz Au, 913kt Zn, 581kt Pb, 88kt Cu and 39kt Sb

2023 RUPICE MINERAL RESOURCE ESTIMATE (‘MRE’) UPDATE

The updated Indicated and Inferred Mineral Resource estimate was prepared by AMC as set out in Table 1. The effective date is 21 July 2023.

Notes:

- The Mineral Resource estimate has been reported in accordance with the requirements of ASX Listing Rule 5.8 and the JORC Code.

- A cut-off grade of 50 g/t silver equivalent has been applied.

- Silver equivalent (AgEq) –was calculated using conversion factors of 31.1 for Zn, 24.88 for Pb, 80.0 for Au, 1.87 for BaSO4, 80.87 for Cu, 80.87 for Sb, and recoveries of 90% for all elements. Metal prices used were US$2,500/t for Zn, US$2,000/t for Pb, US$150/t for BaSO4, US$2,000/oz for Au, US$25/oz for Ag, US$6,500/t for Sb and US$6,500 for Cu.

- The applied formula was: AgEq = Ag(g/t) x 90% + 31.1 x Zn(%) x 90% + 24.88 x Pb(%) * 90% + 1.87 x BaSO4% x 90% + 80 x Au(g/t) x 90% + 80.87 x Sb(%) x 90% + 80.87 x Cu(%) x 90%

- It is the opinion of Adriatic Metals and the Competent Persons that all elements and products included in the metal equivalent formula have a reasonable potential to be recovered and sold.

- Metallurgical recoveries of 90% have been applied in the metal equivalent formula based on recent and ongoing test work results.

- A bulk density (BD) was calculated for each model cell based on its domain, using regression formulas. For the Main zone: BD = 2.66612 + BaSO4 x 0.01832 + Pb x 0.03655 - Zn x 0.02206 + Cu x 0.09279 for the barite high-grade domain, BD = 2.72748 + BaSO4 x 0.02116 + Pb * 0.04472 + Zn x 0.01643 - Cu x 0.08299 for the barite low-grade domain; and for the NW zone: BD = 2.92581 + BaSO4 x 0.01509 + Pb x 0.04377 - Zn x 0.02123 + Cu x 0.10089 for the barite high-grade domain, BD = 2.74383 + BaSO4 x 0.01731 + Pb x 0.04573 + Zn x 0.02023 - Cu x 0.06041 for the barite low-grade-domain (the barite domains were interpreted using 30% BaSO4 cut-off).

- Rows and columns may not add up due to rounding.

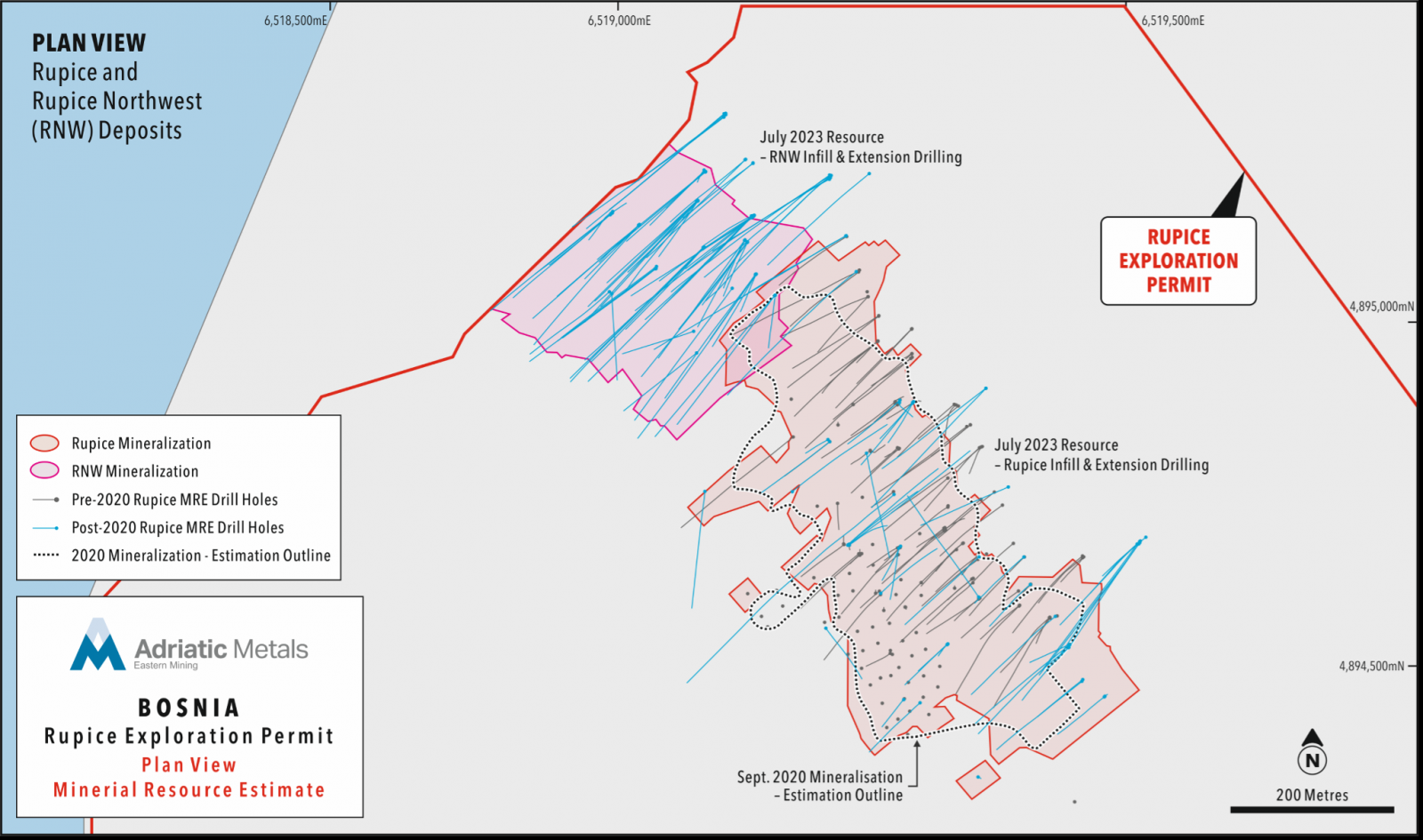

DRILLING AND SAMPLING

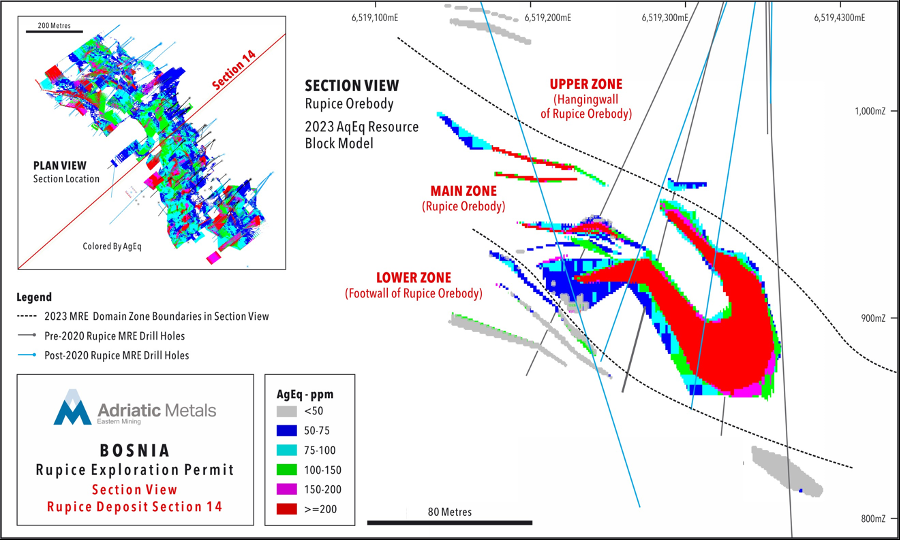

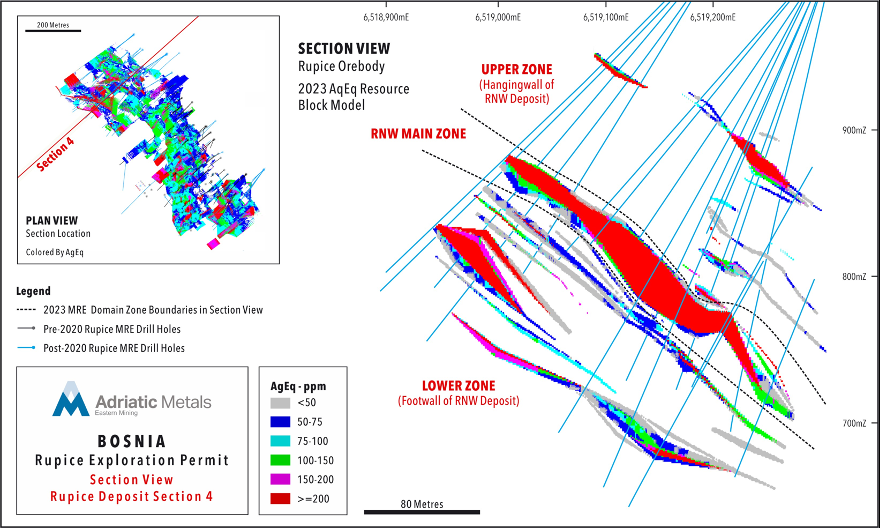

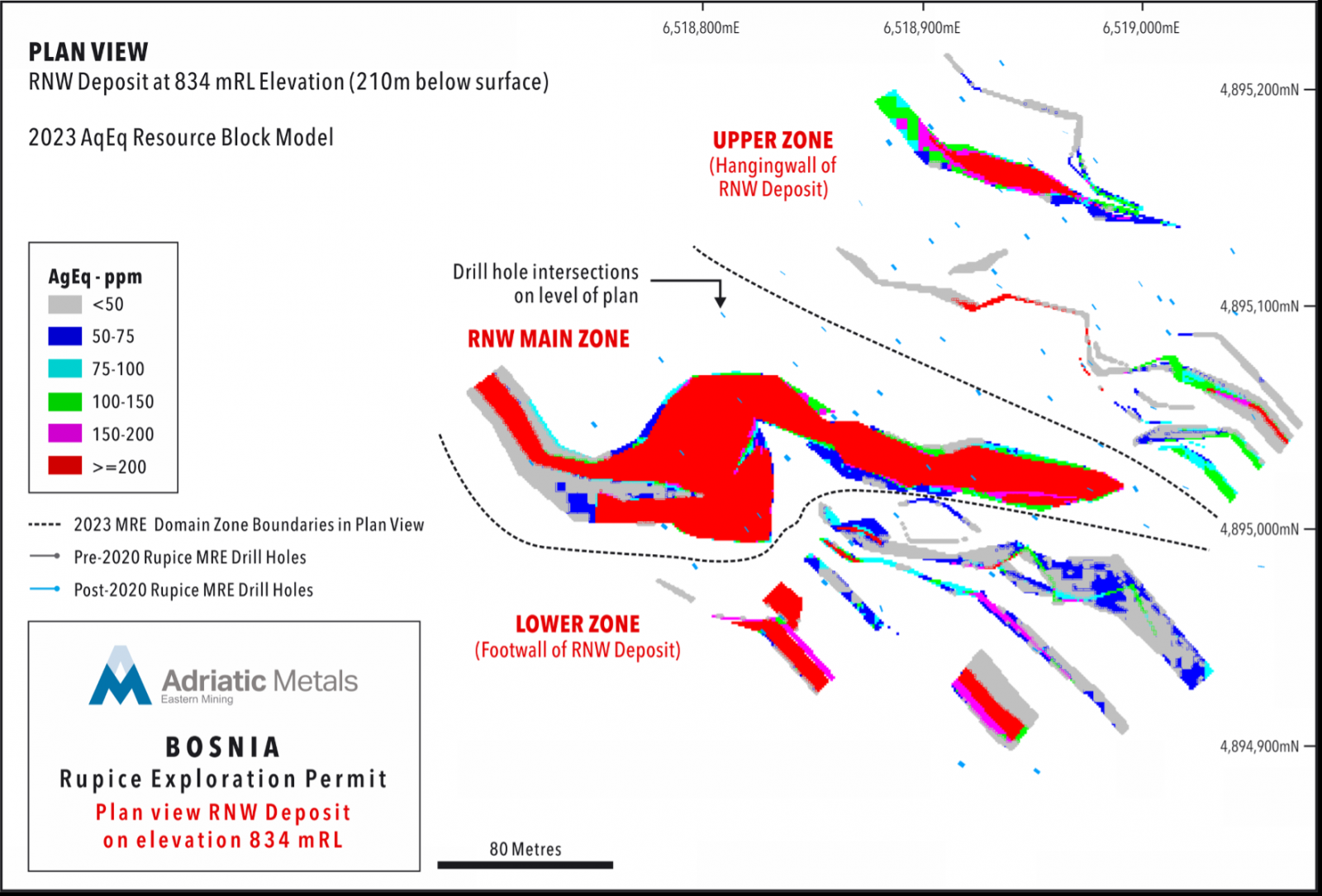

For the 2023 MRE (Rupice and RNW), a total of 287 diamond drill holes for a total of 76,935m define the current limits of the known mineralization. Up to mid-2022, the deposit was drilled and sampled using diamond drill holes on a nominal 20m by 20m spacing. From mid-2022 to May 2023, the drill hole spacing was widened to a 40m x 30m spacing across RNW reflecting the robust continuity of the stratabound mineralization along and across strike. Drilling has defined a combined Rupice and RNW mineralized system having a strike length of >900m and an across-strike width of >350m.

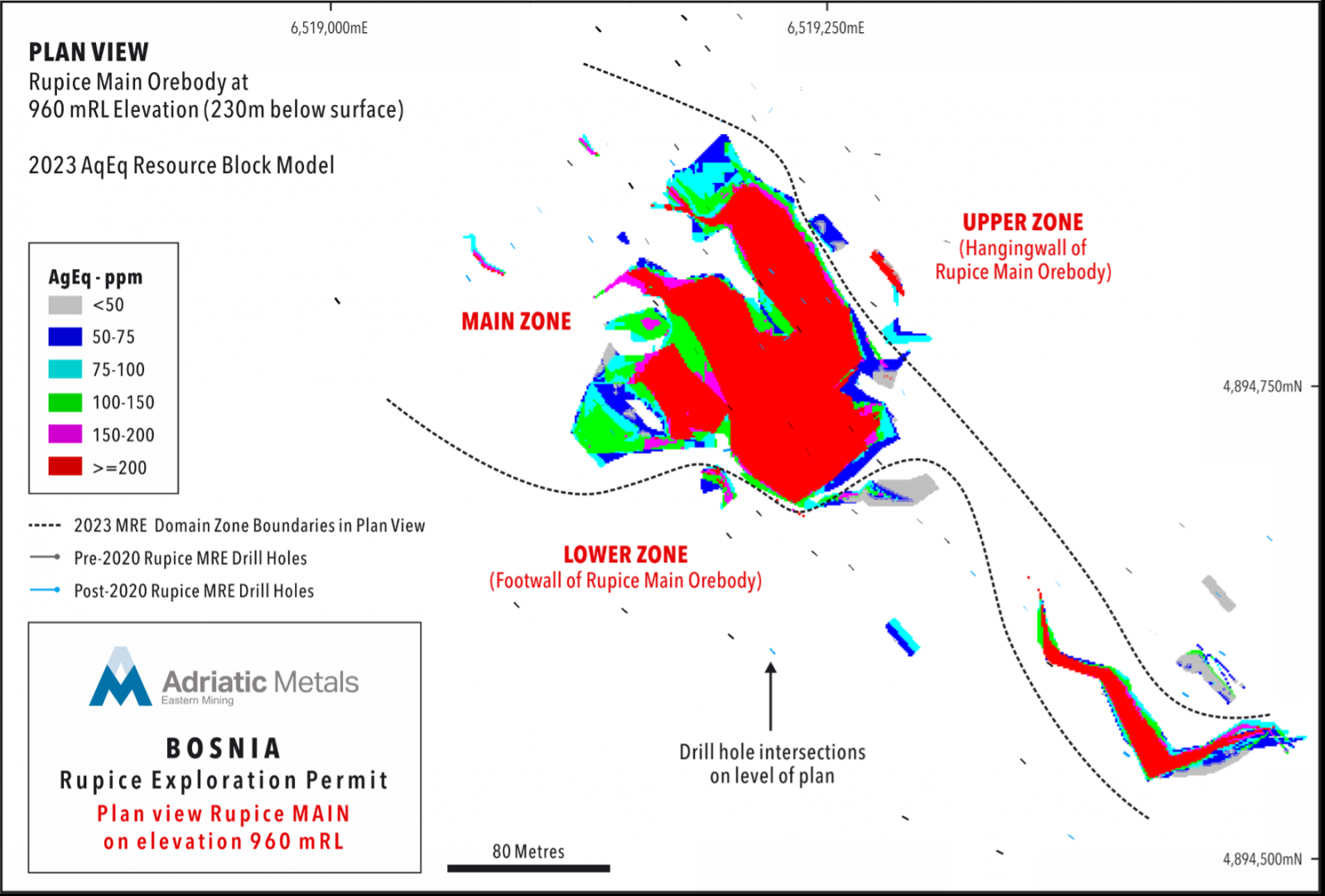

The Rupice portion of the 2023 MRE includes a total of 207 diamond drill holes for a total of 51,228m to define the current limits of known Rupice mineralization. The deposit was drilled and sampled using diamond drill holes on a nominal 20m by 20m spacing up to the end of 2022. Drilling defined the Rupice deposit to have a strike length of >600m and an across-strike width of >350m.

The RNW portion of the 2023 MRE includes a total of 80 diamond drill holes from the Company’s drilling programmes in 2021 to May 2023 for 25,708m to define the current limits of the known RNW mineralization. Up to mid-2022, the deposit was drilled and sampled using diamond drill holes on a nominal spacing of 40m by 20m. From mid-2022 to the end of May 2023 the drill hole spacing was widened to a 40m by 30m spacing. The widening of the drill spacing was in response to the RNW deposit being spatially continuous over its >300m strike length and having a >260m across-strike width.

Drill holes completed by the Company were set up to drill to the southwest with holes dipping from -450 to -860 from horizontal at the surface. Additional drill holes were completed from the opposite direction, and perpendicular to the mineralized trend. All historical holes were vertical and focused on the up-dip portion of the Rupice mineralization.

PQ diameter drill rods were used for pre-collaring in the first 50m to 100m to maintain dip, azimuth and to penetrate broken ground in Jurassic cover sequence stratigraphy. HQ diameter drill rods were used through the main more competent and mineralized Triassic sequence of mixed carbonate and siliciclastic basin sediments. HQ triple tube was used to maximise core recovery and for improved core orientation.

Historic drilling was whole-core sampled. All new drilling was half-core sampled for both Rupice and RNW deposits in the Adriatic Metals exploration core shed in Vares, Bosnia and Herzegovina. Sample preparation, including weighing, drying, crushing and grinding was undertaken at ALS Bor, Serbia prior to October 2022, and at SGS Ankara, Turkey laboratory facilities. Diamond drill core was analyzed by ICP (AES and MS), fire and XRF methods.

Primary assays for Rupice and RNW were processed through the ALS laboratories in Bor (Serbia), Loughrea (Ireland) and Rosia Montana (Romania) to October 2022. As of October 2022, primary samples were processed through SGS Ankara (Turkey) and Lakefield (Canada) laboratories. SGS Bor (Serbia) and ACME Ankara (Turkey) laboratories have been used as Umpire laboratories for external quality assurance / quality control (QAQC) of results.

GEOLOGY AND MINERALIZATION

The host rocks at Rupice and RNW include Middle Triassic limestone, dolostone, calcareous and dolomitic marl, and a range of mostly fine-grained siliciclastic rocks including cherty mudstone, mudstone, siltstone and fine-grained sandstone. The main mineralized horizon is a brecciated dolomitic unit that dips at around 50o to the northeast and has been preferentially mineralized with base, precious and transitional metals. The Triassic sequence has been deformed by early-stage ductile shearing and late-stage brittle faulting.

The Rupice and RNW polymetallic mineralization consists of sphalerite, galena, barite and chalcopyrite with silver, gold, tetrahedrite, boulangerite, bournonite and pyrite. The majority of the high-grade mineralization is hosted within the brecciated dolomitic unit. Fault displacements included in the 2020 MRE were not included in the 2023 update as they were not identified where anticipated in post-2020 underground development and drill core. The majority of deformation is along shears wrapping about the margins of mineralization. This is consistent with the deposit being within a compressional low angle thrust environment mapped on a regional scale. Thickening of the central portion of the Rupice deposit is considered to be associated with thrust related folding. Mineralized widths of up to 65m true thickness are seen in the central portion of the Rupice deposit.

RNW is less deformed than Rupice. Differential shearing along the deposits’ massive sulphide boundaries appears to have created a large sigmoidal structure which hosts the polymetallic mineralization. Effectively a large lozenge with tapering ends in section-view that gently rolls-over to the west.

Rupice sits at a stratigraphically higher position than RNW. They are separated by a ferruginous siliceous chert unit (GYD). Rupice and RNW overlap at their strike extremities over an interval of ~80m. The area between Rupice and RNW is referred to as the ‘GAP’. In the area of the GAP both Rupice and RNW lenses progress from massive to semi-massive to disseminated sulphides.

To date, the massive sulphide mineralization at Rupice has a defined strike length of >600m, with a maximum true-width thickness of around 65m and a minimum of 0.3m. Mineralization at Rupice still remains open to the northwest and to the southeast along strike. In the existing areas drilled, the up-dip portions of Rupice are yet to be closed-off to the southwest. This presents a significant opportunity for further resource growth at Rupice over its strike length.

To date, the massive sulphide mineralization at RNW has a defined strike length of >300m, with a maximum true-width thickness of around 40m and a minimum of 0.4m. The mineralization increases in width, grade and thickness from southeast to northwest. RNW has been drilled to the northern extent of the Rupice Exploitation License boundary. There is no geological reason to believe mineralization does not extend beyond the Exploitation License boundary to the northwest. Adriatic Metals plc has applied to the Zenica-Doboj Canton to expand the Concession Agreement along strike of RNW. Mineralization also remains open up-dip to the southwest. The deposit south-eastward is narrowing with increasing base metal content, higher grades, elevation in copper and gold values, and a reduction in barium content.

MODELLING AND GRADE INTERPOLATION

The geological controls on polymetallic mineralization at Rupice and RNW were interpreted using lithological, alteration, structural and geochemical data available from logging and assays. Separate solids for each lithology from surface to below mineralization were modelled. Massive and semi-massive visually logged sulphides where combined to form coherent mineralized solids. The trends in mineralization were matched to modelled stratigraphic units controlling the distribution of mineralization.

Faulting (2020) previously inferred to displace mineralization was not identified in post 2020 underground development and within drill core where anticipated. No major steep offsets are visible in the Jurassic cover sequence. Shear zones define hanging wall and footwall mineralization contacts associated with the major Rupice and RNW mineralized bodies. The shearing is interpreted to be thrust related and likely responsible for areas of thicker mineralization. The current mineralization and geological interpretation assumes the majority of movement is compressional and sub-parallel to mineralization, controlling the geometry of mineralization thickening and thinning.

Multiple high-grade and low-grade mineralized solids exist as satellite stratabound mineralized bodies on the hanging wall and in the footwall of continuous bodies of massive sulphide mineralization.

The majority of satellite mineralized solids have been modelled to capture isolated mineralization at various elevations and associated with different parts of the stratigraphic sequence. The majority of smaller, discontinuous, poorly informed and low-grade solids are not included in either Inferred or Indicated mineralization as they are currently considered uneconomic. The subgrade solids are there to identify areas: of future mineralization potential, of low-grade mining dilution, for potential acid rock drainage, and for mine planning.

Statistical analysis of modelled domains shows that the main mineralized brecciated dolomite has a bi-modal population for the majority of the elements being modelled. The higher-grade populations clustered spatially and were subsequently individually interpreted and wireframed.

All the domains were interpreted on a section-by-section basis and were used to generate three-dimensional (3D) ‘solid’ wireframes. The same method was applied for the individual high-grade and low-grade populations for each modelled main element.

Once mineralization and domains for each element were interpreted and wireframed, classical statistical analysis was repeated for the samples within the interpreted domains. Drill data was composited to 2m down hole intervals for the Main zone and 1m down hole intervals for the Northwest zone. Boundary statistical analyses and top-cuts were determined and applied where appropriate.

The geostatistical analysis generated a series of semi-variograms that were used during grade estimation. The semi-variogram ranges determined from the analysis contribute to the determination of the search neighbourhood dimensions. All variograms were calculated and modelled using composited sample files, constrained by the corresponding mineralized envelopes for each element. Where low-grade and high-grade domains were modelled, samples were combined for both domains to make sure that the number of samples was sufficient for robust geostatistical analysis. It was found that absolute semi-variograms were difficult to model for most of elements, and therefore, relative pair-wise variograms were modelled for all elements.

The bulk density values were calculated for each model cell based on its domain and regression formula. Domains included Main zone, high-grade barite, low-grade barite, and northwest domains. The formulas were derived using scattergrams for density versus BaSO4, Pb, Cu and Zn grades.

A block model was constructed, constrained by the interpreted mineralized envelopes. A parent cell size of 5m(E) x 5m(N) x 5m(RL) was adopted with standard sub-celling to 1m(E) x 1m(N) x 1m(RL) to maintain the volumetric resolution of the mineralized lenses.

Grades for all ten elements were interpolated into the empty block model using the Ordinary Kriging method and a “parent block estimation” technique, i.e., all sub-cells within a parent cell were populated with the same grade. The ordinary kriging (OK) process was performed at different search radii until all cells were interpolated. The search radii were determined by means of the evaluation of the semi-variogram parameters, which determined the kriging weights to be applied to samples at specified distances. Hard boundaries were honoured between each modelled lens and each grade domain.

Block grades were validated both visually and statistically and all modelling was completed using Micromine software.

CLASSIFICATION AND REPORTING

Clause 20 of the JORC (2012) Code requires that all reports of Mineral Resources must have reasonable prospects for eventual economic extraction, regardless of the classification of the resource. The Rupice deposit has reasonable prospects for eventual economic extraction on the following basis:

- Metallurgical test work by WAI has confirmed that Rupice mineralization is amenable to flotation processes;

- Metallurgical test work has confirmed that a barite concentrate should meet API specifications;

- A marketing study by a leading consultant in the field of barite confirmed that there is an opportunity to enter the market as a niche player leveraging logistical advantages for a supplier located in Bosnia and Herzegovina;

- The cut-off grade adopted for reporting (50 g/t Ag equivalent) is considered reasonable given the Mineral Resource will be exploited by underground mining methods and potentially processed using flotation techniques to produce a concentrate or as a direct shipping crushed product for massive ores.

- The Vares Project Definitive Feasibility Study (August 2021) demonstrated that the deposit has a positive post-tax net present value (NPV) of USD 1,062M; a post-tax internal rate of return (IRR) of 134%; a payback period of 0.7 years; and that the mineralized zone is mineable using underground methods under the given economic scenario and parameters.

- The Project has an Ore Reserve estimation reported in accordance with the JORC Code, which was published in August 2021. This Ore Reserve pre-dates the July 2023 Mineral Resource estimation update and as such is not inclusive of the additional tonnage incorporated with the addition of the RNW mineralization.

- The Vares Project is fully funded.

- Concentrate off-take agreements and transport logistics have all been negotiated.

- Adriatic Metals has secure long-term tenure across all tenements.

- All permits and licenses from the Bosnian and Herzegovinian Government (Federal, State, Cantonal) are in good standing and as required to mine and produce base and precious metals concentrates.

- Two underground declines and underground development are in progress. First ore has been intersected on 15 July 2023 in a planned development drive. The accuracy of the Reserve is confirmed.

- Construction of the Vares Processing Plant is in progress with first concentrate product as of Q4 2023.

The Rupice Mineral Resource classification criteria is based on the geological understanding of the deposit, geological and mineralization continuity, drill hole spacing, QAQC results. The MRE is reported by classification in Table 1, above a cut-off grade of 50 g/t AgEq with the effective date of 21 July 2023.