DFS - Capital and Operating Cost Estimate

Bosnian Definitive Feasibility Study

15 September 2021

Capital and Operating Cost Estimate

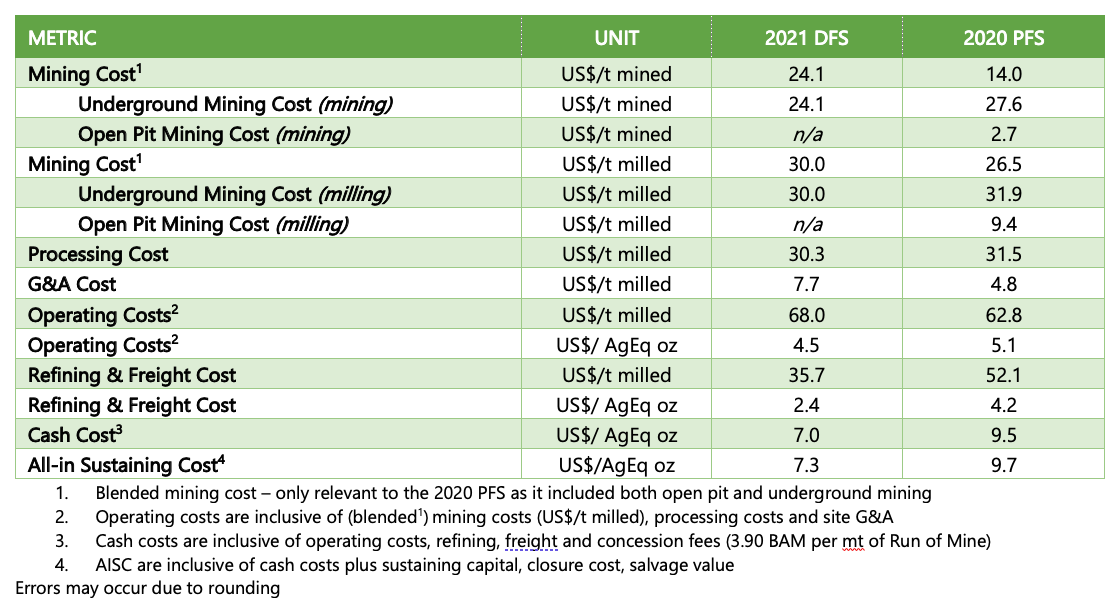

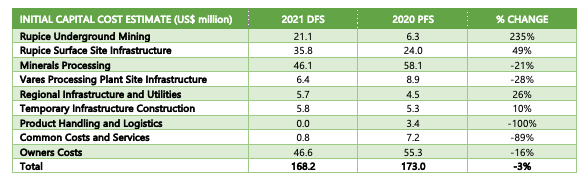

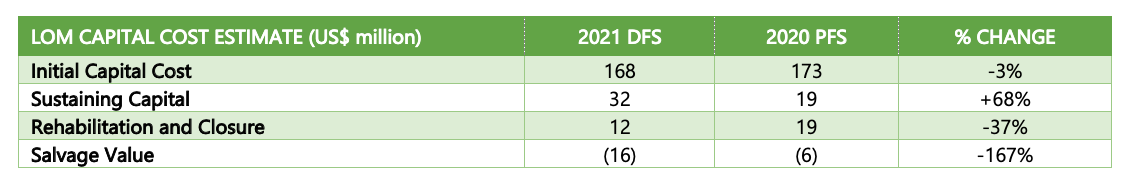

The capital and operating cost estimates were compiled by Ausenco with inputs from other engineering consultants and the Company. All estimates have been prepared using estimated quantities and quoted unit costs. The Initial Capital Costs and Life of Mine (“LOM”) capital costs are summarised in the Tables 4 and 5 below.

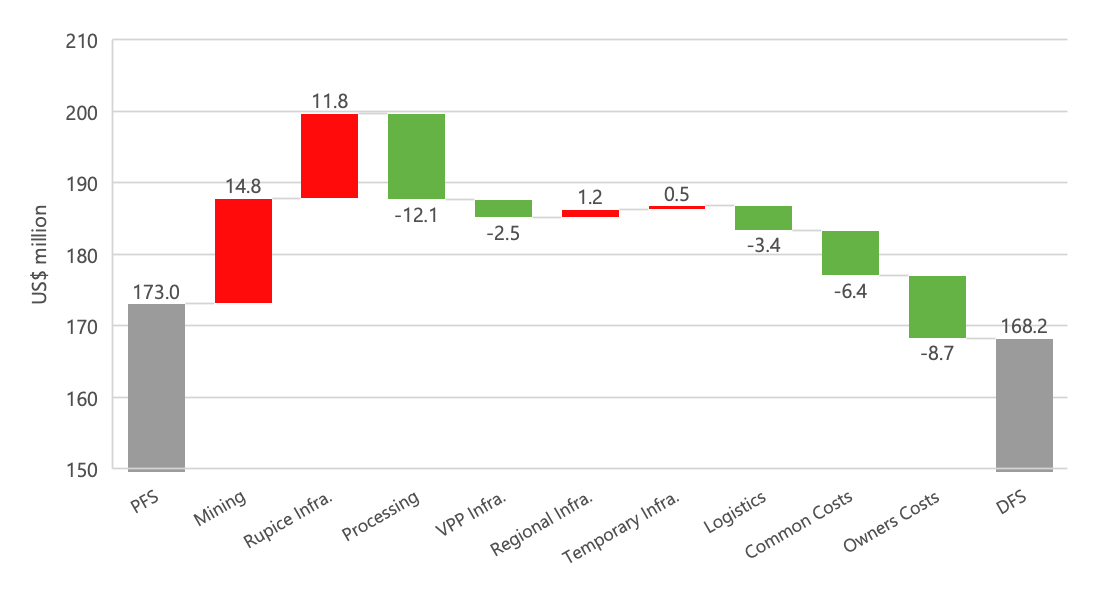

The underground mining costs increased due to the re-classification of operating costs to capital expenditure, reflecting an advancement in the timing of that expenditure. In addition, the optimisation of the crushing plant and expanded footprint at the Rupice Surface Infrastructure, to accommodate larger stockpiles, resulted in an increase in the volume of earthworks in comparison to the 2020 PFS. These increases in capital expenditure are largely offset by savings from the exclusion of the barite and sulphide (pyrite) circuits in the Vares Processing Plant. Including the other items noted below, the net reduction in Initial Capital Cost is US$5 million from the 2020 PFS estimate to US$168 million.

Table 4: Initial Capital Cost Estimate

Chart 1: Changes in Initial Capital Cost Estimate from 2020 PFS to 2021 DFS (US$ million)

Summary of Changes in Initial Capital Costs

Mining

- The total increase in mining costs is the result of the reassignment of costs previously included as operating costs in the 2020 PFS, to Initial Capital Costs to reflect the early mining activities

Rupice Infrastructure

- Upgrading the crushing plant to three-stage crushing, reallocated US$1.8 million in costs from the Vares Processing Plant

- Additional earthworks (from 0.45M cubic metre to 1.8M cubic metre) required for the larger stockpile area and associated infrastructure, increased costs by US$6.8 million

- More accurate pricing in haul road costs accounted for an increase of US$2.7 million

- The addition of shotcrete batching and mixing to the backfill plant (US$0.9 million) as well as heating added for water and aggregate, increased costs by US$1.1 million

Processing

- The upgrading of the crushing plant at Rupice Surface Infrastructure negated the need for a SAG mill at the Vares Processing Plant, saving US$1.8 million

- The removal of the processing equipment associated with the barite and pyrite circuits saved US$6.1 million, as well as associated building and concrete costs (US$2.0 million)

Regional Infrastructure

- There was a saving of US$4.5 million as the haul road was recategorised to the main earthworks (Rupice Surface Infrastructure)

- Additional costs of US$5.7 million for electrical connection costs, most of which is additional, as supply company now requires payment for new line, in addition to a connection fee.

Logistics

- The 2020 PFS assumed US$3.4 million in improvement costs at Ploce port, Croatia, which are not required

Common Costs

- Significant savings in freight (US$4.2 million) due to reduction in equipment used for barite and pyrite concentrate, as well as associated specialist consultants and vendor costs (US$2.2 million)

Owners Costs

- Saving of US$8.7 million in Engineering Procurement and Construction Management (“EPCM”) costs, Owner’s costs and contingency and some re-assignment of capital costs to other cost categories

In addition to the changes in the Initial Capital Cost estimates as provided above, sustaining capital increased by US$13 million due to the increased size of the stockpile terrace, backfill plant replacement pumps and additional pipe reticulation. Rehabilitation and closure costs reduced, reflecting savings arising from not mining Veovaca.

Table 5: LOM Capital Cost Estimate

Table 6: LOM Average Operating Costs